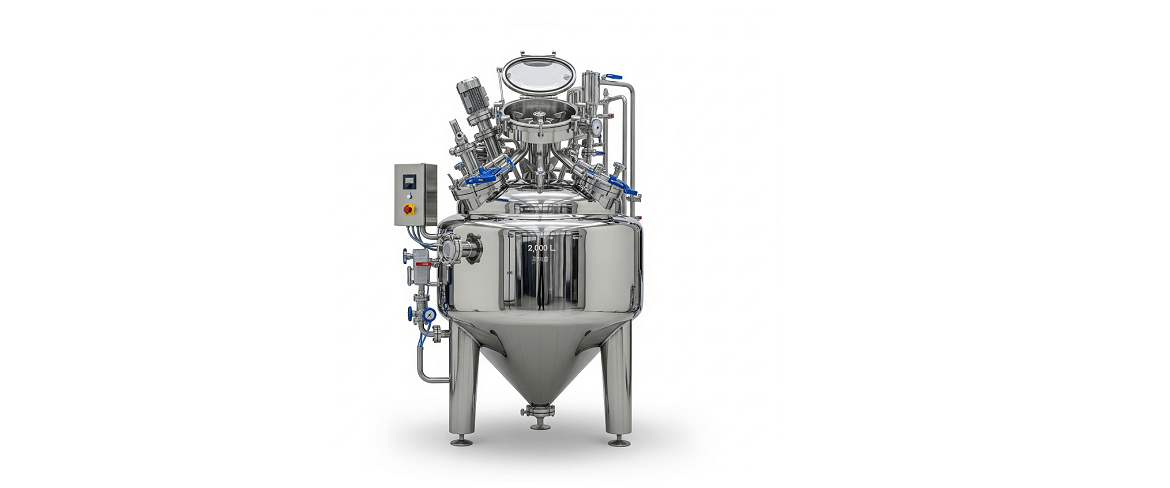

A pharmaceutical mixing vessel is a specialized container designed to mix and blend various pharmaceutical ingredients to create a homogeneous mixture. These vessels are crucial in the pharmaceutical manufacturing process, where precise control of mixing parameters is essential to ensure the quality and consistency of the final product.

Sizes available from 25 Liter to 1000 Liter.